Protecting Fragile Items: Choosing the Right Packaging

Share

We all clear that strike during transit is hard to avoid. Especially for fragile items, they are more likely to get damaged facing with the impact. This requires us to prepare special protective packaging for it. Generally speaking, there are two methods to protect fragile items. The first one is to add a lining of appropriate size to the paper tube packaging. Liners are typically foam or custom shaped paper liners. The second is to choose high-quality paper materials.

Custom Lining of Packaging

Let's look at the first method. Lining of packaging has a mature production system in our factory. We can make materials into fixed shapes and sizes according to customers' requirements. And these are to be able to firmly fix the customer's product in the package, so that it will not be displaced with the bumps in transportation, which will eventually lead to product damage. In addition, these liners act as cushioning. Obviously, this can well remove the impact force, so that the products will not squeeze each other. These have effectively reduced the loss rate of products during transportation. Whether it is for brands or consumers, this has extraordinary value. Costs are reduced to a great extent.

Utilizing High-Quality Paper Materials

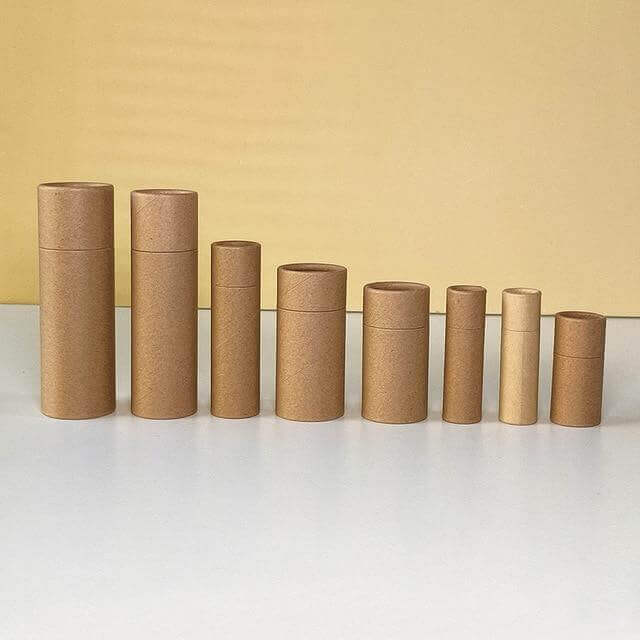

You know, paper materials can be divided into many categories. In packaging paper, chipboard is definitely in the ranks of high-grade raw material paper. Its hardness and color expression when printing are excellent. Therefore, it is an excellent choice whether it is a simple shipping package or a high-end packaging with beautiful graphics. The materials used by Esytube to make paper tubes are cardboard. There are many types of cardboard, including Duplex Chipboard, Black Chipboard, Natural Kraft Chipboard, customized color Chipboard, and Gray Chipboard. You can choose different paper tubes according to the needs of the product. To check whether a paper tube meets the requirements, we have a series of inspection standards.

Inspection standard of paper tube

The first is the inspection of the appearance of paper tubes. If there is glue on the paper tubes or the packaging has been damaged, they will be picked out and disposed of. Only products that are qualified in appearance and do not affect sales will enter the next inspection process, which is the detection of the lid of the paper tube. Whether the lid of the paper tube is firm or not directly affects the safety of the goods inside. If the cover of the paper tube can be pulled out without much force, it is also a substandard product, and such a cover is easy to fall off during transportation. If the cover is too strong, it needs a lot of force to pull it out and needs to be improved. Such a cover is inconvenient to use. In addition, it is also necessary to test the support performance of the paper tube, which is to ensure the display effect of the paper tube on the shelf.

The next step is to test the compression resistance of the paper tube, which requires the use of a press. Put the paper tube on the press and test how much force can crush the paper tube. If the inner diameter is within 80mm, the required force must be greater than 800 N to be qualified; if the inner diameter is between 80mm and 250mm, the required force must be greater than 1000 to be considered qualified; if the inner diameter is greater than 150mm, the required force must be greater than 1200 be considered qualified.

Esytube: Safeguarding Your Shipments

The above is all the content of this blog. If you are interested in our paper tubes, you can click here to view our official website, which contains various types of paper tubes. Of course, if you have any questions about the production process of the paper tube or the printing technology, you are also welcome to consult by email.