How Cardboard Tubes Are Made: From DIY Crafts to Industrial Production

Partager

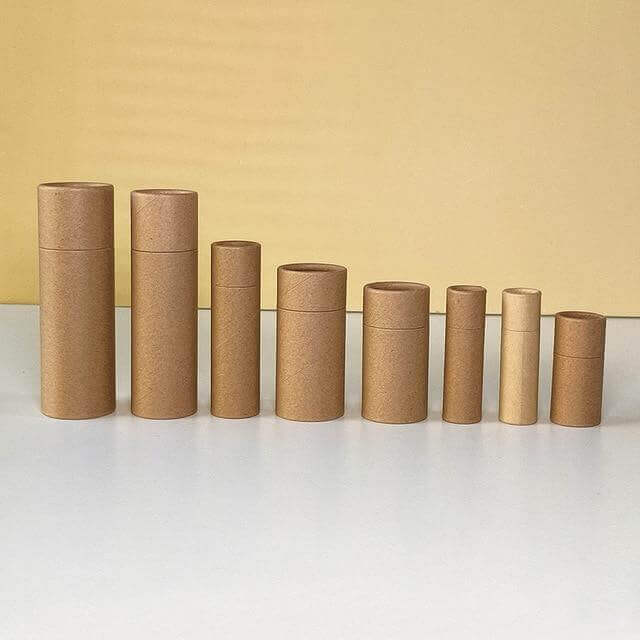

1 . Why People Want to Make Cardboard Tubes

Cardboard tubes are everywhere—from your favorite craft projects to the core of shipping and packaging solutions. But have you ever wondered how they’re actually made? Whether you're a DIYer with glue on your fingers or a business owner looking for sustainable packaging, this guide walks you through both worlds: how to make cardboard tubes by hand, and how they’re made at scale in a factory.

· Step-by-step instructions for DIY cardboard tubes.

· How factories produce industrial-scale cardboard tubes.

Read on to discover the best approach for your needs.

2 . DIY Guide:How to Make Cardboard Tubes at Home

Want to make cardboard tubes at home? Here’s a simple guide to help you create your own for crafts or small projects.

Materials and Tools You'll Need

· Thin cardboard or kraft paper (recycled sheets work well)

· Cylindrical mold (like a PVC pipe or rolling pin)

· Strong adhesive (PVA glue or hot glue)

· Scissors or utility knife

· Ruler and pencil

· Optional: masking tape, waterproof coating, or paint

Step-by-Step Instructions

1 . Cut the cardboard into strips based on the desired tube size.

2 . Wrap the strips tightly around your mold, applying glue between each layer.

3 . Hold the tube in place for a few minutes while the glue sets.

Tip : Use masking tape to hold the edges in place as it dries—this helps keep its shape.

4 . Once dry, carefully remove the tube from the mold and trim the edges if needed.

How to Make Your Tubes Stronger or Waterproof

· For extra strength, add more layers of cardboard.

· Use stronger adhesive or reinforce the interior with filler.

· Apply a waterproof coating for durability in moist environments.

What Can You Do With DIY Paper Tubes?

· Organize cables or small tools.

· Use them as plant starters or seedling pots.

· Craft wall art, toys, or decorations.

· Prototype packaging ideas for mass production.

3 . Inside the Factory: How Industrial Cardboard Tubes Are Made

In factories, cardboard tubes aren’t just rolled together—they’re engineered for precision and strength. Depending on the end use, manufacturers choose between spiral winding or convolute winding. Here's a closer look at what happens behind the scenes.

Materials Used in Industrial Paper Tube Making

· Kraft paper or recycled paperboard for strength.

· PVA-based adhesives for bonding.

· Optional: coatings or printed layers for customization, depending on the end use (e.g., mailing tubes or luxury packaging).

Spiral vs. Convolute Winding: What’s the Difference?

Spiral Winding: Paper is wound diagonally around a rotating mandrel, suitable for mailing, packaging, and industrial cores.

Convolute Winding: Paper is wrapped straight around the mandrel in layers, giving a cleaner finish for retail packaging and containers.

Here's a quick visual to show how spiral and convolute winding differ.

Paper Tube Production Process Explained

1. Cut paper strips and apply adhesive.

2. Winding the paper onto a rotating mandrel (either spirally or convolutely).

3. Drying and curing the tube for strength.

4. Final trimming and finishing to required size.

5. Optional customization: printing, labeling, lining, embossing

4. DIY vs. Industrial Tubes: Which Is Better for You?

|

Factor |

DIY Paper Tubes |

Industrial Paper Tubes |

|

Cost |

Low for small projects |

Economical in bulk |

|

Strength |

Weaker |

Strong and consistent |

|

Customization |

Easy for small projects |

High for large orders |

|

Production Time |

Takes longer |

Fast, efficient in bulk |

|

Best For |

Crafts, small projects |

Packaging, industrial use |

Summary:

DIY tubes are perfect for small, creative projects, while industrial tubes are ideal for high-strength and large-scale applications.

5 . Real-World Applications of Cardboard Tubes

Cardboard tubes are widely used across many industries:

E-commerce Packaging : For shipping posters and artwork.

Mailing Tubes : Protect documents or products during shipping.

Industrial Cores : Holding materials like textiles, tapes, and films.

Display Packaging : In retail and exhibitions for customized stands.

Crafts & DIY Projects : Making planters, storage containers, and decorations.

Food Packaging : For premium brands, offering an eco-friendly and unique presentation.

6 . Why Sustainable Paper Tube Packaging is the Future

Sustainable packaging is becoming the future of the industry:

· Eco-friendly Materials : Less environmental impact than plastic

· Lower Carbon Footprint : Producing paper tubes typically results in less environmental impact compared to plastic.

· Recyclability and Reusability : Ideal for eco-conscious consumers and brands

Businesses adopting paper tube packaging can align with global sustainability trends and attract environmentally aware customers.

7 . Ready to Start Your Cardboard Tube Project?

From DlY cardboard tubes to industrial-scale production, this guide has equipped you with everything you need to know, Now, you're ready to confidently choose the best packaging solution for your needs!

lf you're looking for a reliable and eco-friendly cardboard tube supplier, feel free to leave a message or request a quote. We'd love to work with you to find a smarter, more sustainable packaging solution.

8 . FAQ: Quick Answers

What can I do with DIY cardboard tubes?

Crafting, planting, organizing, toys.

What types of cardboard tubes exist?

Spiral-wound, convolute-wound, and parallel-wound.

Best cardboard for crafts?

Recycled kraft or chipboard.

How to make cardboard stronger?

Add more layers, use stronger glue, or reinforce the inside with filler.