What Different Categories Does Packaging Fall Into?

Partager

Packaging plays a crucial role in the lifecycle of a product, from manufacturing to the end consumer. It serves multiple purposes, including protection, communication, and facilitating logistics. In this blog, we will explore the various categories of packaging, their functions, and how to choose the right type of packaging for your product.

What Purpose Do Packaging Materials Serve & Why Do We Need Them?

Packaging is crucial for more than just containing a product; it serves several important functions. It provides essential protection by shielding items from physical damage, such as impacts and vibrations, and by offering barrier protection against environmental factors like moisture, dust, and light. Packaging can also include tamper-evident features to ensure product safety and integrity. Additionally, it plays a key role in containment, preventing spills and leaks, organizing small components, and facilitating the efficient transportation and storage of bulk items.

Beyond protection and containment, packaging serves as a vital communication tool, providing necessary product information, establishing brand identity, and meeting legal requirements. It enhances convenience through features like resealable closures, portability, and portion control. With increasing environmental awareness, modern packaging also focuses on sustainability by reducing waste, promoting recyclability, and utilizing biodegradable or reusable materials to minimize environmental impact.

What Are the Different Types of Packaging?

Packaging is typically categorized into three main types: Primary, Secondary, and Tertiary. Each type serves specific functions in the product lifecycle and supply chain.

What Is Primary Packaging?

Primary packaging is the first layer of packaging that comes into direct contact with the product. It’s what consumers typically interact with and see on store shelves. The main purposes of primary packaging are:

- Product Containment: It holds the actual product, whether it’s a liquid, solid, or gas.

- Protection: It shields the product from contamination and damage.

- Preservation: For perishable goods, primary packaging often includes features to extend shelf life.

- Information Display: It usually carries essential product information and branding.

Examples of primary packaging include:

- Bottles and Cans: Used for beverages, cleaning products, and many liquid items.

- Blister Packs: Common for pharmaceuticals and small electronics.

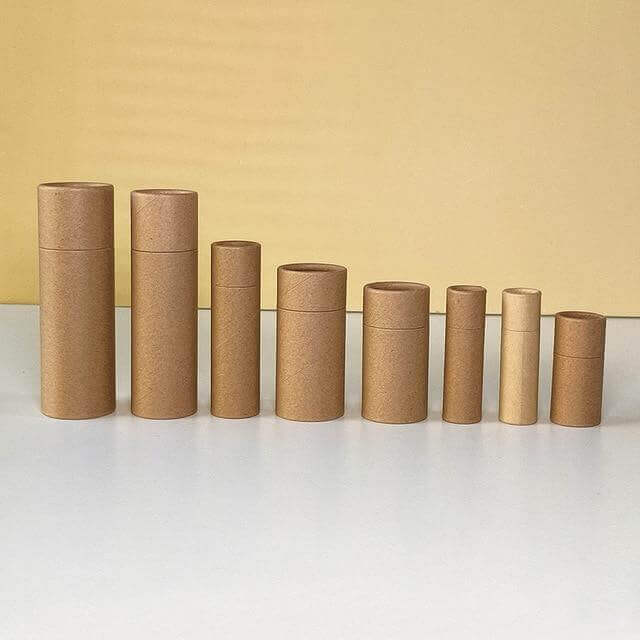

- Tubes: Used for toothpaste, cosmetics, and some food products.

- Wrappers: Found on candies, snacks, and many food items.

- Jars: Used for preserves, spreads, and some beauty products.

- Pouches: Increasingly popular for pet food, snacks, and some liquid products.

Primary packaging is often designed to be visually appealing and user-friendly, as it’s a key factor in consumer purchasing decisions. It needs to balance functionality with marketing appeal, often incorporating easy-open features, resealable options, and clear branding elements.

What Is Secondary Packaging?

Secondary packaging groups multiple units of primary packaging together. Its main functions are:

- Bundling: It combines individual units for easier handling and distribution.

- Additional Protection: It provides an extra layer of protection during transportation and storage.

- Display: In retail settings, secondary packaging often serves as a display unit.

- Branding: It offers additional space for branding and marketing messages.

Examples of secondary packaging include:

- Cardboard Boxes: Used to contain multiple primary packages, such as a box holding several cereal boxes or cans.

- Shrink Wrap: Often used to bundle multiple bottles or cans together.

- Display Boxes: Designed to showcase products on retail shelves while containing multiple units.

- Corrugated Trays: Used in supermarkets to hold and display products like canned goods.

Secondary packaging plays a crucial role in logistics and retail operations. It needs to be sturdy enough for transportation but also designed for easy unpacking and attractive display in stores. Many retailers have specific requirements for secondary packaging to fit their shelving and display systems.

What Is Tertiary Packaging?

Tertiary packaging is used for bulk handling, warehouse storage, and shipping. Its primary functions are:

- Bulk Protection: It safeguards large quantities of products during transportation and storage.

- Efficient Handling: It allows for easy movement of large product quantities with forklifts or pallet jacks.

- Load Unitization: It consolidates many smaller packages into one large, manageable unit.

- Transportation Optimization: It’s designed to maximize the use of space in trucks, containers, and warehouses.

Examples of tertiary packaging include:

- Pallets: Wooden or plastic platforms used to stack and move large quantities of boxed products.

- Stretch Wrap: Plastic film wrapped around palletized goods to secure them in place.

- Crates: Large, sturdy boxes used for shipping heavy or bulky items.

- Drums: Used for transporting liquids or powders in bulk.

- Shipping Containers: The largest form of tertiary packaging, used for international shipping.

Tertiary packaging is rarely seen by the end consumer but is vital for efficient supply chain operations. It needs to be extremely durable to withstand the rigors of long-distance transportation and multiple handling points.

What Is the Most Eco-Friendly Packaging?

As environmental concerns become more pressing, the search for eco-friendly packaging solutions has intensified. Eco-friendly packaging focuses on reducing environmental impact by using sustainable materials and practices.

Among the most effective options are recycled paper and cardboard, which are widely recyclable, biodegradable, and derived from renewable resources. These materials are commonly used for boxes, cartons, and paper bags. However, the energy required for their production can be considerable.

Biodegradable plastics, like PLA from corn starch and PHA from microorganisms, decompose faster than traditional plastics and reduce long-term waste, though they need specific conditions to break down and may not fit existing recycling systems. Glass and metals, including aluminum and steel, are eco-friendly as well. Glass is infinitely recyclable and inert but energy-intensive to produce and transport. Metals are durable and highly recyclable, though they require significant energy initially.

Plant-based materials like bamboo, hemp, and sugarcane bagasse are renewable and often biodegradable, contributing to a lower carbon footprint. However, their applications can be limited, and scaling production can be challenging. Compostable packaging is designed to break down into natural elements in composting environments, leaving no harmful residues, but it requires specific composting conditions and may not decompose in home compost systems. Reusable packaging, such as refillable containers and durable shopping bags, extends the lifecycle of packaging materials and helps reduce waste, although it often requires higher upfront costs and consumer participation.

When evaluating eco-friendly packaging, it’s essential to consider the entire lifecycle, from the sourcing of raw materials and the energy and water used in production, to transportation efficiency and end-of-life disposal. The packaging must still fulfill its primary functions of protecting the product and ensuring its quality throughout the supply chain while also fitting consumer recycling and disposal habits.

How to Determining the Best Packaging Choice?

Choosing the best packaging for a product requires a careful balance of multiple factors. Initially, the product's characteristics dictate the packaging choice. Key considerations include the product's physical state—solid, liquid, or gas—which affects the type of containment needed. Additional factors like perishability, fragility, size, shape, weight, and chemical properties play crucial roles in determining the appropriate packaging to ensure protection and functionality.

Supply chain logistics also significantly impact packaging decisions. Considerations include the method of transportation (air, sea, or land), distance, climate conditions during transit, and handling practices. Packaging must be durable enough for long journeys and various environmental conditions, and should facilitate efficient handling and storage.

Cost and sustainability are critical aspects to balance as well. Packaging decisions should weigh material and production costs against benefits such as protection and marketing appeal. Sustainability considerations involve using recyclable or renewable materials, reducing waste, and ensuring energy-efficient production. Additionally, packaging must comply with regulatory requirements, reflect brand identity, and be user-friendly. Modern packaging often incorporates technology for added functionality, and it should be scalable to adapt to changes in production volume and market expansion.

By carefully considering these factors, businesses can choose packaging that not only protects their product but also enhances its value, meets regulatory requirements, aligns with sustainability goals, and resonates with consumers. The right packaging choice is a balance of functionality, cost-effectiveness, environmental responsibility, and marketing potential. For further information, click here.