2 main structures of paper tube packaging, 6 different customization options

Partager

Paper tubes come in various types. We can distinguish them by the color, material, and printing method. I was wondering if you were aware that paper tubes can also be split from their structure.

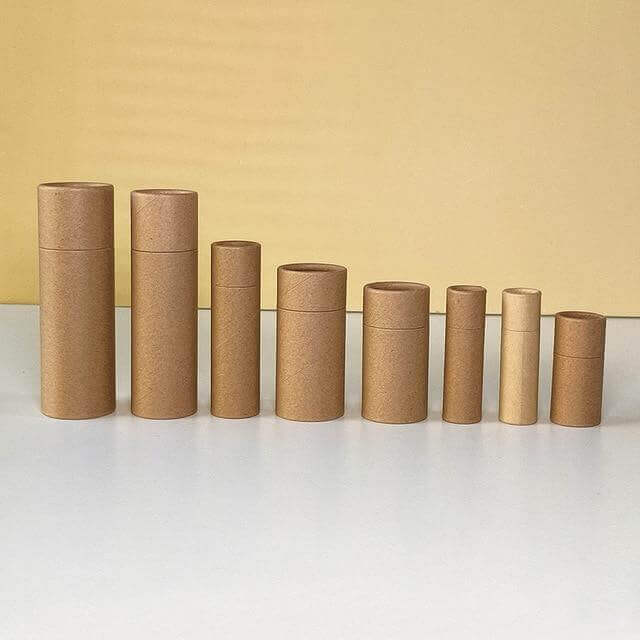

Generally speaking, we can roughly distinguish them into 2-piece paper tubes and 3-piece paper tubes by the number of paper tube components.

2-piece paper tubes

As its name suggested, 2-piece paper tubes consist of 2 parts: the cap and the base. It includes 3 main styles.

*The first style paper tube has a solid base and a separate cap that fits tightly onto the open end. Its base is usually consisted of 2-4 layers of paper material, depending on the specific requirements. While the base supplies a secure infrastructure to the paper tube, its cap acts as a protective lip, ensuring the contents inside are well-protected.

*The second paper tube has a longer cap than its base. This type of paper tube structure cancels the traditional collar and takes an independent, complete bottom instead, which brings it more printing space than other paper tubes.

But I wouldn’t recommend this style of paper tube for start-up brands, despite it offers ample printing space to realize your dream design. That is because this kind of paper tube takes more material to produce. And that would lead to a higher cost.

* Different from the previous two paper tubes, this style has a limited range of applications. You can say it is specially designed for lipsticks, lip balms, and deodorant. Its user-friendly design only requires customers to turn the bottom of the tube to use. So, it is also known as twist-up paper tubes. What is more, paper tubes of this style are always produced in small sizes around 20 mm in diameter and 70 mm in length. Its tiny body makes it one of the most easy to carry packaging.

3-piece paper tubes

You can easily infer that a 3-piece paper tube has one more part than the preceding 2-piece paper tubes. That is the shaker mechanism. This special part allows items like salt, and other Spices and Seasonings to be shaken out of the tube. And it can also be divided into 2 styles according to the different shakers.

* The shaker mechanism is equal in length to the body of the paper tube. This is one of the most common structures in paper shaker tubes. Its shaker mechanism can be taken out intact from the tube body. And that is a perfect container for holding some tiny stuff after use.

*The shaker mechanism is shorter than the body of the paper tube. Compare with the previous style, this one is simpler to package products.

Composite can

Besides the above cardboard tubes, we also manufacture composite cans to create a better-sealed option for you. The biggest difference between normal paper tubes and composite can lie in their caps and bottom ends. The former is made from 100% degradable cardboard, and the latter is made of various materials including iron, aluminum foil, and cardboard.

For products like tea and potato chips that have a special requirement for their packaging’s air tightness, we would recommend the following composite can. It is sealed with an aluminium foil layer to help maintain the freshness and quality of the products inside the tube. Also, you can choose a mental lid for your products. Both these two styles of composite paper tubes are carefully designed to keep the contents inside well for storing and transporting.

Custom paper tubes is allowed in Esytube

Esytube had produced thousands of paper tubes for our clients. And we gained some experience from that. If you have met something paper tube relevant troubles you in your customizing period, maybe we could be helpful. You could send an email to us at sales@esytube.com for help.