Elevating Packaging Production with Sustainable Paper Tubes

Compartir

In the realm of product manufacturing, packaging serves as the crucial link between creation and consumption. With the evolution of technology and shifts in market demands, packaging production continually evolves and innovates. Within this dynamic landscape, paper tube packaging emerges as a sustainable and adaptable solution, embodying the essence of modern packaging excellence. From its origins to its current prominence, the evolution of paper tube packaging mirrors the intricate interplay of technological advancements, consumer preferences, and environmental consciousness.

Importance of Paper Tube Packaging Production:

1.1 Significance of Paper Tube Packaging:

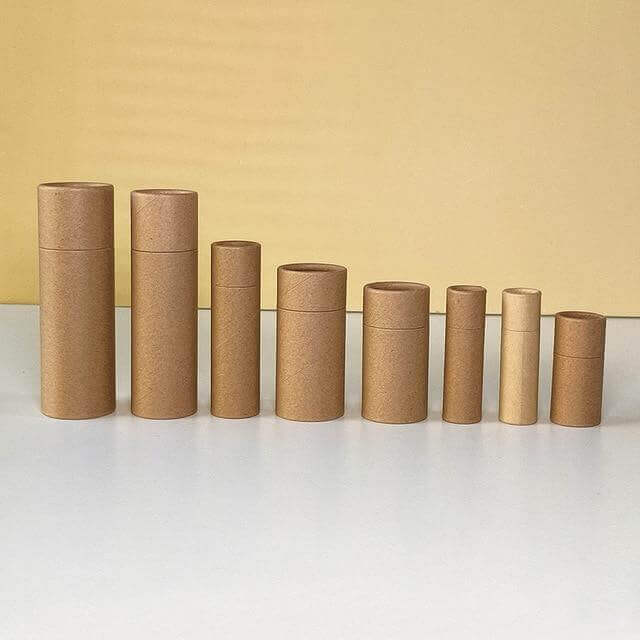

At the core of functionality and sustainability lies paper tube packaging, offering a multifaceted solution for product containment. Its cylindrical design not only elevates product presentation but also ensures sturdy protection, safeguarding contents during handling and transit. Moreover, paper tube packaging embodies sustainability by utilizing renewable resources and promoting eco-conscious consumption. Opting for paper tubes aligns with consumer preferences for environmentally friendly packaging, contributing to global sustainability efforts while fulfilling practical and aesthetic needs.

1.2 Role of Paper Tube Packaging:

In the competitive landscape of commerce, brand differentiation is essential, and paper tube packaging emerges as a potent tool for brand enhancement. Through unique designs, customizations, and branding elements, paper tubes convey brand values and narratives, fostering deeper connections with consumers. Additionally, the tactile experience of handling paper tube packaging enhances consumer interactions, leaving a lasting impression and nurturing brand loyalty. Thus, paper tube packaging transcends its utilitarian role to become a tangible expression of brand ethos, enriching the overall consumer experience.

Understanding Paper Tube Packaging Manufacturing Processes and Facilities:

2.1 Key Steps in Paper Tube Packaging Manufacturing:

The production of paper tube packaging involves a meticulous process, beginning with the selection of premium paperboard materials. These materials undergo cutting, shaping, adhesion, and winding stages, each contributing to the formation of the cylindrical structure. Modern manufacturing facilities employ advanced equipment such as precision cutting tools and automated winding systems to ensure efficiency and consistency. Stringent quality control measures are integrated to uphold product integrity, meeting industry standards and customer expectations.

2.2 Necessary Facilities and Modern Equipment Utilized:

State-of-the-art facilities are imperative for efficient paper tube packaging production. Equipped with specialized machinery, these facilities handle various production aspects, from material preparation to final assembly. Precision cutting tools guarantee accurate dimensions, while automated winding systems streamline cylindrical structure formation. Moreover, stringent quality control measures, including rigorous testing and inspection protocols, ensure the highest product quality and consistency. Leveraging modern equipment and facilities, manufacturers optimize paper tube packaging production to meet evolving market needs efficiently.

The Impact of Design and Quality Control on Paper Tube Packaging Production:

3.1 How Packaging Design Influences Brand Perception and Consumer Engagement:

Packaging design plays a pivotal role in shaping brand perception and influencing consumer behavior. In the case of paper tube packaging, design elements such as color, typography, and imagery communicate brand values effectively, resonating with the target audience. A well-executed design not only catches the eye but also evokes emotions, creating memorable experiences and fostering brand loyalty. Investing in thoughtful and impactful packaging design is essential for brands seeking to differentiate themselves in the competitive market landscape.

3.2 The Importance of Stringent Quality Control Measures:

Maintaining product quality is paramount in paper tube packaging production. Stringent quality control measures are implemented throughout the manufacturing process to ensure durability, functionality, and aesthetic appeal. From material selection to manufacturing processes, every aspect undergoes rigorous testing and inspection to identify and rectify defects. This commitment to quality not only safeguards product integrity but also enhances brand reputation and customer satisfaction. By adhering to strict quality control measures, manufacturers instill confidence in consumers, demonstrating their commitment to delivering reliable and premium-quality paper tube packaging solutions.

Paper Tube Packaging’s Influence on Shipping Costs:

4.1 Analysis of Packaging Design and Material Impact on Shipping Costs:

Packaging design and material choices significantly influence shipping costs for paper tube products. Bulky or heavyweight packaging materials increase transportation expenses due to higher shipping weights and volumes. Conversely, lightweight and compact designs optimize space utilization, minimizing shipping costs. Material choices also affect packaging durability, influencing shipping costs by reducing the likelihood of product damage or returns. Selecting packaging materials and designs that balance product protection with shipping efficiency helps mitigate costs while ensuring product integrity.

4.2 Strategies for Optimizing Packaging to Minimize Shipping Expenses:

Optimizing packaging dimensions and materials is key to reducing shipping expenses without compromising product integrity. Lightweight yet durable materials, such as high-strength paperboard, minimize packaging weight while providing adequate protection. Space-efficient designs, such as slim-profile tubes or collapsible structures, maximize cargo space utilization and minimize wasted space during transportation. Additionally, sustainable packaging practices, such as right-sizing packaging to minimize material usage, contribute to cost savings and environmental sustainability. Prioritizing packaging optimization enhances supply chain efficiency and profitability.

Paper Tube Packaging as a Brand Identity Statement:

5.1 Paper Tube Packaging's Role in Conveying Brand Values:

Paper tube packaging serves as a canvas for brand expression, communicating values, aesthetics, and narratives to consumers. Through thoughtful design elements, brands create memorable experiences and foster connections with consumers. Whether conveying elegance or sustainability, paper tube packaging embodies brand ethos, differentiating products in the marketplace.

5.2 High-Quality Paper Tube Packaging's Brand Differentiation:

High-quality paper tube packaging acts as a brand signature, distinguishing products and reinforcing brand credibility. Premium finishes and durability enhance perceived product value, attracting discerning consumers. By investing in high-quality paper tube packaging, brands establish reputations for excellence and elevate market presence. Thus, paper tube packaging becomes a strategic asset for brand differentiation and market success.

Navigating Paper Tube Packaging Dynamics for Success

In the dynamic landscape of packaging production, paper tube packaging emerges as a versatile, sustainable, and impactful solution. From enhancing product presentation to promoting sustainability, paper tube packaging embodies modern packaging excellence. Leveraging design innovation, quality control, and eco-friendly practices, Esytube navigate paper tube packaging production with efficiency and reliability. As consumers prioritize sustainability and brand experience, paper tube packaging becomes a strategic asset for brand differentiation and market success. By embracing innovation and industry trends, businesses unlock the full potential of paper tube packaging to deliver exceptional products and experiences, ensuring long-term success in the competitive market landscape. If you want to know more paper tube packaging, sent us an email at sales@esytube.com.