6 Reasons Paper Food Tubes Are Taking Over Eco Packaging

Share

1. Introduction

At ESYTube, we specialize in food-grade paper tube packaging that blends sustainability, food safety, and standout shelf appeal. As global consumers become increasingly conscious of environmental impact, brands face rising pressure to embrace eco-friendly alternatives.

Among various sustainable options, paper tube packaging for food has emerged as a frontrunner. Its recyclability, compostability, and design flexibility make it an ideal solution for modern, green-minded brands.

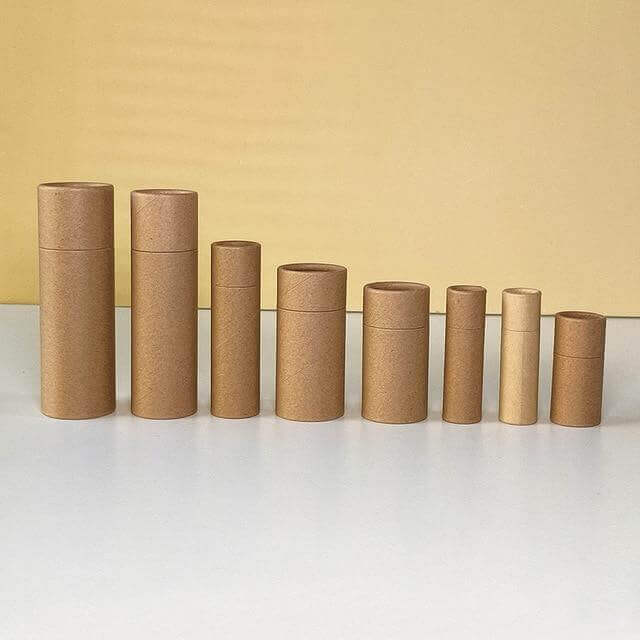

2. What Is Paper Tube Packaging for Food?

Food-grade paper tube packaging is a cylindrical container made from certified food-safe paperboard. It typically consists of:

Tube Body: Constructed from multi-layer, FDA-approved paperboard.

Inner Liner: Made of PE, PLA, or foil to provide moisture and oil resistance.

Closure: Sealed with screw-caps, snap-lids, or heat-seal films to maintain freshness.

This packaging is widely used for products like nuts, granola, tea, spices, and protein powder—offering not just protection, but also strong shelf appeal.

3. 6 Advantages of Food-Grade Paper Tube Packaging

Here are six compelling reasons why paper food tubes are quickly replacing traditional packaging:

Eco-Friendly: Made from renewable materials, paper tubes are recyclable or compostable, helping reduce plastic pollution.

Food Safe: All materials meet FDA/EU food-contact standards, ensuring safe storage with no contamination or off-tastes.

Branding Power: The smooth exterior supports high-quality printing, embossing, foil stamping, and more—making your product stand out.

Extended Shelf Life: Airtight closures and barrier liners lock out moisture and air, keeping contents fresh longer.

Lightweight & Cost-Efficient: Easier to ship and store compared to heavier glass or metal containers.

Consumer Appeal: Its natural, premium look and feel strongly appeal to eco-conscious customers and elevate perceived product value.

4. Applications in the Food Industry

Paper tube packaging has proven its versatility across a wide range of food categories, offering both practicality and visual appeal:

Nuts & Snacks

Paper tubes provide an effective moisture barrier, keeping products like almonds, trail mixes, and dried fruits fresh and crunchy. The resealable tops offer convenience for on-the-go snacking and portion control, especially popular among health-conscious consumers.

Tea & Spices

For specialty teas and seasoning blends, paper tubes allow small-batch custom printing, which is ideal for boutique brands. The round shape and premium look enhance shelf presence, while inner foil or PLA linings protect delicate aromas and flavors.

Protein & Health Powders

Larger-diameter paper tubes are perfect for protein powders, collagen mixes, or smoothie boosters. They are easy to scoop from and can be designed with resealable caps for daily use. The sturdy outer layer supports bold branding that appeals to fitness and wellness markets.

Pet Treats

Paper tubes are a fun and practical choice for pet snack brands. Their eco-friendly image aligns with pet owners’ growing preference for sustainable products, while custom artwork and playful colors boost shelf impact. They’re also great for subscription boxes or trial-sized products.

5. How to Customize Your Food Paper Tubes

When customizing paper tube packaging for food, it’s important to select specifications that best suit your product type, storage needs, and branding goals. Here’s a guide to help you decide:

Tube Dimensions

Choose the diameter and height based on the product’s volume, usage habits, and desired shelf presence.

For example:

Small tubes (Ø 40–60 mm, height 50–100 mm) work well for teas, spices, mints, or single-serve snacks.

Medium tubes (Ø 70–100 mm, height 100–200 mm) are ideal for granola, dried fruits, or powdered mixes.

Large tubes (Ø 110–150 mm, height 200–300 mm) suit protein powders, bulk snacks, or pet treats.

Closure Options

Choose a sealing method based on freshness requirements and product frequency of use:

Screw-caps are great for resealable, daily-use items like protein powder or granola.

Snap-lids are simple, cost-effective closures for lightweight dry goods.

Foil seals offer tamper evidence and freshness protection, ideal for one-time-use or premium teas.

Inner Liners

Select liner material depending on barrier needs and sustainability goals:

PE or PET: Good moisture barriers for nuts, snacks, and powders.

PLA (bioplastic): Suitable for eco-conscious brands wanting compostable options.

Foil: Best for high-oil content or aroma-sensitive products like spices and teas.

Printing & Surface Finishes

Align printing method with order quantity and branding intent:

Digital printing: Best for prototypes or small batches.

Flexo or offset printing: Cost-efficient for bulk orders.

Enhancements: Add foil stamping, embossing, or matte lamination for premium look & feel.

Optional Add-ons

Consider extras to enhance function or marketing:

QR codes: Link to product info, recipes, or brand story.

Hang-tags or ribbons: For gift packaging or seasonal promotions.

MAP (Modified Atmosphere Packaging): To extend shelf life of sensitive foods.

6. Compliance and Sustainability Certifications

To bolster consumer trust, highlight certifications such as:

FDA Food-Contact Compliance (U.S.).

FSC or PEFC for responsibly sourced paper.

EN 13432 industrial-compostability standards.

FAQ

Q1: How do paper food tubes compare to plastic cans?

A1: Paper food tubes deliver comparable barrier performance with a much lower carbon footprint and are fully recyclable or compostable.

Q2: Can I store wet or oily foods in paper tubes?

A2: Yes—choosing an appropriate inner liner like PLA or PET plus a foil seal allows safe storage of oily or moist foods.

Q3: Are paper food tubes suitable for microwave or oven use?

A3: No—paper tubes are made for dry storage and should be removed before any heating.

Q4: What is the minimum order quantity for custom paper tubes?

A4: Typical minimum orders start at 1,000–2,000 units, depending on size, finish, and liner selection.

Q5: How should consumers recycle or dispose of paper food tubes?

A5: Consumers should peel off plastic lids and liners, then recycle or compost the remaining paper tube.

7. Conclusion

Paper tube packaging for food delivers on all fronts: environmental stewardship, food safety, branding flexibility, and cost savings. As more consumers demand sustainable options, brands that lead the way in eco-packaging will gain a lasting competitive edge.