What is digital printing for packaging and how it works?

Partager

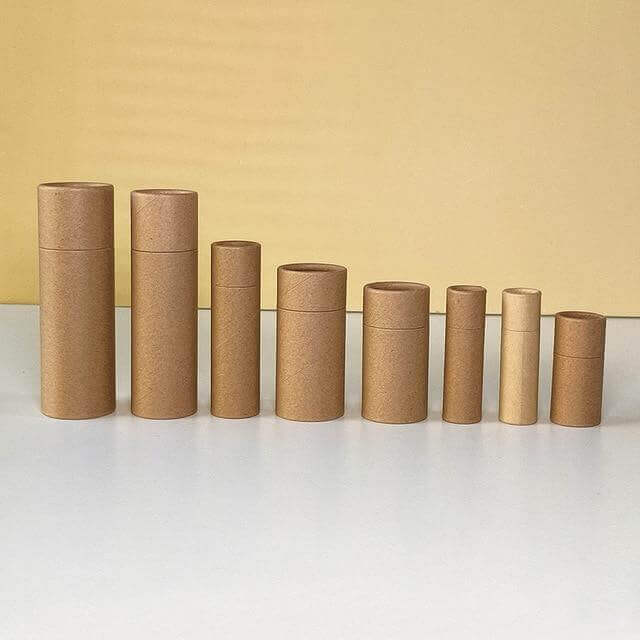

As a paper tube packaging supplier, we clear that both material and printing method play important role in production. And in this blog, we goona explore the incredible digital printing method in the packaging industry, discover how digital printing revolutionizes packaging, minimizing waste, setup costs, and turnaround times. Dive into its strategic benefits, environmental advantages, and real-world applications. Join us as we uncover how Esytube's expertise in digital printing elevates packaging strategies to new heights.

1. Understanding Digital Printing in Packaging

Definition and Concept of Digital Printing for Packaging:

Digital printing for packaging refers to the process of using digital technology to print packaging materials directly from digital files. This method eliminates the need for traditional printing plates, making it a more efficient and cost-effective solution for producing high-quality, custom packaging. Digital printing allows for precise control over the print quality and color accuracy, making it ideal for creating vibrant and detailed packaging designs.

Evolution of Digital Printing Technology in the Industry:

The evolution of digital printing technology has been marked by significant advancements in speed, quality, and versatility. Initially, digital printing was limited to small-scale applications due to its high costs and lower print speeds. However, with technological advancements, it has become a mainstream option for packaging, capable of producing large volumes with exceptional quality. Innovations such as high-speed inkjet and electrophotographic printing have expanded the possibilities for digital printing in packaging, enabling more intricate designs and shorter production cycles.

Digital Printing vs. Traditional Printing Methods:

Traditional printing methods, such as flexography and lithography, rely on printing plates and extensive setup processes, making them less flexible and more time-consuming. In contrast, digital printing does not require plates, allowing for faster turnaround times and easier design modifications. While traditional methods are still preferred for very large runs due to cost efficiencies at scale, digital printing excels in short runs, customization, and producing detailed, high-quality prints without the extensive setup and waste associated with traditional techniques.

2. Advantages of Digitally Printed Flexible Packaging

Efficiency in Turnaround Time:

Digital printing offers a significant reduction in production time compared to traditional printing methods. Since it eliminates the need for printing plates and extensive setup, digital printing can quickly transition from one design to another. This efficiency is particularly beneficial for businesses that need to meet tight deadlines or respond rapidly to market changes. By streamlining the production process, digital printing enables faster delivery times, helping companies stay competitive and responsive.

Ease of Dynamic Design Changes:

One of the most compelling advantages of digital printing is the ability to make real-time adjustments to packaging designs without incurring additional setup costs. This flexibility allows brands to experiment with different designs, colors, and messages, tailoring their packaging to specific campaigns or market segments. The ease of updating designs ensures that packaging can be kept current and relevant, enhancing the brand's ability to engage with consumers and adapt to trends swiftly.

Cost-Effectiveness of On-Demand Printing:

On-demand printing is a cost-effective approach that allows businesses to print only the quantities they need, significantly reducing waste and inventory costs. Unlike traditional printing methods that require large print runs to be economical, digital printing supports short runs, minimizing excess production and storage expenses. This approach not only conserves resources but also enables businesses to test new designs and products without the risk of overproduction, leading to more efficient and sustainable operations.

Flexibility for Short-Run and Promotional Packaging:

Digital printing opens up new possibilities for short-run, seasonal, and promotional packaging campaigns. Brands can quickly produce limited editions or special designs for holidays, events, or promotions without the constraints of traditional printing methods. This capability allows for greater creativity and marketing agility, enabling brands to capture consumer interest with unique and timely packaging. By leveraging digital printing, companies can execute targeted campaigns that resonate with their audience and drive sales.

Environmental Benefits of Digital Printing:

Digital printing is a more environmentally sustainable option compared to traditional printing methods. It produces less waste by allowing for precise print runs and minimizing excess production. Additionally, digital printing typically uses less energy and fewer resources, contributing to a smaller carbon footprint. The ability to print on demand further enhances its sustainability, as it reduces the need for large inventories and the associated storage and disposal costs. By choosing digital printing, companies can demonstrate their commitment to environmental responsibility.

Innovative Capabilities of Digital Printing Technology:

Digital printing technology offers advanced capabilities that set it apart from traditional printing methods. These include variable data printing, which allows for personalized packaging with unique text, images, or codes for each item. This capability is particularly useful for marketing campaigns, product tracking, and enhancing consumer engagement. Additionally, digital printing supports high-resolution graphics and vibrant colors, ensuring that packaging designs are eye-catching and of superior quality. These innovative features enable brands to differentiate themselves and create memorable packaging experiences.

3. Partnering with a Digitally Printed Flexible Packaging Manufacturer

Selecting the Right Packaging Partner:

Selecting the right packaging partner is crucial for maximizing the benefits of digital printing. A knowledgeable and experienced partner can provide valuable insights into the best practices for digital printing, ensuring that your packaging meets the highest standards of quality and efficiency. They can also offer guidance on design optimization, material selection, and production processes, helping you achieve the desired results while staying within budget. Partnering with a reliable provider ensures a seamless transition to digital printing and ongoing support for your packaging needs.

Esytube's Expertise in Digital Printing:

Esytube's expertise and capabilities are perfectly aligned with the demands of digital printing. With a team of skilled professionals and state-of-the-art equipment, Esytube is equipped to handle complex printing projects with precision and efficiency. Our commitment to innovation and quality ensures that every package we produce meets the highest standards of excellence. By leveraging our deep understanding of digital printing technology, we help our clients achieve their packaging goals and stand out in a competitive market.

4. Exploring Digital Printing Techniques

Understanding Flatbed Digital Printing:

Flatbed digital printing is a versatile technology that involves printing directly onto a wide range of substrates using a flat surface. This method is ideal for producing high-quality, detailed prints on materials such as cardboard, plastic, and metal. Flatbed printers can handle large and irregularly shaped items, making them suitable for a variety of packaging applications, from custom boxes to promotional displays. The ability to print directly onto substrates eliminates the need for additional mounting or lamination processes, streamlining production and reducing costs.

Comparing Different Printing Methods:

Traditional printing methods, such as flexography, lithography, gravure, and screen printing, each have unique characteristics and applications. Flexography is known for its high-speed production and versatility in printing on various materials. Lithography offers excellent print quality and is widely used for commercial printing. Gravure is ideal for long runs with consistent quality, while screen printing is favored for its ability to produce vibrant colors and durability on a range of surfaces. However, these methods often involve longer setup times and higher costs compared to digital printing.

Advantages and Disadvantages of Printing Methods:

Flexography is cost-effective for large runs but less flexible for short runs and design changes. Lithography provides high-quality prints but requires complex setup and is less efficient for short runs. Gravure delivers consistent quality for large volumes but has high initial setup costs. Screen printing excels in color richness but is labor-intensive and less suitable for fine details. Digital printing, on the other hand, offers quick setup, flexibility, and high-quality prints for both short and long runs, though it may be more costly for extremely large volumes compared to traditional methods.

Why Digital Printing Excels:

Digital printing stands out due to its unmatched flexibility, allowing for quick design changes and customization without the need for extensive setup. It provides high-quality prints with vibrant colors and fine details, ensuring that packaging designs are visually appealing and effective. The efficiency of digital printing lies in its ability to produce short runs economically, reducing waste and inventory costs. This combination of flexibility, quality, and efficiency makes digital printing an ideal choice for modern packaging needs, enabling brands to respond swiftly to market demands and consumer preferences.

5. Harnessing the Printing Advantage

Real-World Benefits of Digital Printing:

Many businesses have successfully harnessed the advantages of digital printing to enhance their packaging strategies. For instance, a cosmetics company used digital printing to create limited edition packaging for a seasonal product line, resulting in increased sales and customer engagement. A food manufacturer leveraged digital printing to produce customized packaging for different regions, catering to local tastes and preferences. These examples demonstrate how digital printing can drive brand differentiation and market responsiveness, ultimately leading to business growth and success.

Maximizing ROI with Custom Packaging:

To maximize ROI with digital printing, businesses should focus on leveraging its customization capabilities to create unique and targeted packaging. This includes using variable data printing for personalized marketing, designing eye-catching graphics that stand out on shelves, and producing short runs for special promotions or seasonal products. Additionally, businesses can reduce costs and waste by printing on demand and minimizing excess inventory. By strategically utilizing digital printing, companies can enhance their brand presence, engage customers more effectively, and achieve a higher return on investment.

Empowering Brands with Esytube's Solutions:

Esytube's digital printing solutions empower brands to differentiate themselves in a crowded market. Our advanced printing technology enables the creation of high-quality, custom packaging that reflects a brand's identity and values. Whether it's for a product launch, promotional campaign, or everyday packaging needs, Esytube's expertise ensures that each package is a powerful marketing tool. By partnering with us, brands can take advantage of our innovative solutions to create packaging that not only protects their products but also captures consumer attention and drives sales.

Digital Printing Packaging Solutions by Esytube

In conclusion, digital printing offers numerous advantages for packaging, which enable businesses to create unique and engaging packaging that stands out in the market. By adopting digital printing, companies can enhance their packaging strategies and respond swiftly to market trends and consumer demands.

If you need custom designs, short-run printing, or innovative packaging concepts, Esytube are here to help. Discover how our solutions can meet your specific needs and elevate your packaging to the next level. Contact us today to learn more about our services and how we can support your packaging goals.

Contact Information for Inquiries:

For inquiries and consultations, please contact us at:

- Email: sales@esytube.com

- Phone: +86 18329092593