The Versatile World of Large Cardboard Tubes

Aktie

Large cardboard tubes, as the name suggests, are cylindrical structures made primarily of cardboard. Their purpose spans across various industries, serving as essential components in construction, packaging, shipping, and artistic endeavors. These tubes are typically manufactured from layers of rolled cardboard, providing structural integrity while remaining lightweight and cost-effective.

Brief History

The history of cardboard tubes dates back to the late 19th century when cardboard, a versatile and inexpensive material, gained popularity for packaging and industrial applications. However, it wasn't until the mid-20th century that large cardboard tubes became prevalent, owing to advancements in cardboard manufacturing techniques and increased demand in various sectors.

Characteristics of Large Cardboard Tubes

Size and Dimensions

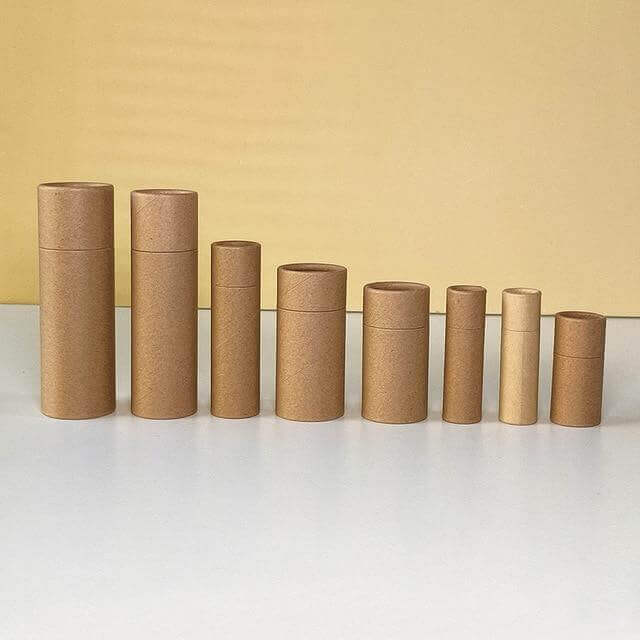

Large cardboard tubes come in a variety of sizes and dimensions, ranging from a few inches to several feet in diameter and length. Their size often depends on the intended application, with larger tubes commonly used in construction and industrial settings, while smaller ones find utility in packaging and artistic endeavors.

Strength and Durability

Despite their lightweight nature, large cardboard tubes boast impressive strength and durability, capable of withstanding considerable loads. This resilience is attributed to their construction, which typically involves multiple layers of sturdy cardboard rolled and bonded together. When engineered correctly, these tubes can support heavy materials and withstand external pressures, making them invaluable in demanding environments.

Versatility in Usage

One of the most remarkable attributes of large cardboard tubes is their versatility in usage. From serving as concrete formwork on construction sites to protecting delicate artwork during shipping, these tubes adapt to a myriad of applications with ease. Their inherent flexibility allows for creative solutions in diverse industries, making them indispensable tools for engineers, artists, and manufacturers alike.

Applications of Large Cardboard Tubes

Construction Industry

In the realm of construction, large cardboard tubes play a vital role in formwork applications. By using these tubes as molds, contractors can create cylindrical structures such as columns, pillars, and piers with remarkable efficiency. Once the concrete sets, the cardboard formwork is easily removed, leaving behind a seamless finish. This method not only accelerates construction timelines but also reduces material waste and labor costs.

Packaging and Shipping

Large cardboard tubes are a staple in the packaging and shipping industry, offering a reliable solution for transporting oversized or delicate items. Whether it's posters, maps, or industrial machinery components, these tubes provide a protective enclosure that safeguards the contents from damage during transit. Additionally, their lightweight nature helps minimize shipping costs and environmental impact compared to traditional packaging materials.

Creative and Artistic Uses

Artists and designers have long recognized the creative potential of large cardboard tubes, using them as raw materials for sculptures, installations, and architectural prototypes. The cylindrical shape lends itself to endless possibilities, whether it's crafting immersive environments or constructing whimsical structures. Moreover, the affordability and accessibility of cardboard tubes make them ideal for educational projects and community art initiatives, fostering creativity and collaboration.

Industrial and Manufacturing Applications

Beyond construction and art, large cardboard tubes find applications in various industrial and manufacturing processes. From serving as cores for winding textiles and films to acting as spools for wire and cable, these tubes provide essential support and containment functions. Their customizable dimensions and structural integrity make them well-suited for niche applications across diverse sectors, contributing to operational efficiency and product quality.

Advantages of Large Cardboard Tubes

Lightweight and Cost-Effective

One of the primary advantages of large cardboard tubes is their lightweight construction, which facilitates easy handling and transportation. Unlike metal or plastic alternatives, cardboard tubes are significantly lighter, reducing strain on workers and minimizing logistical challenges. Additionally, their cost-effectiveness makes them an attractive option for businesses seeking affordable yet reliable packaging and storage solutions.

Eco-Friendly and Sustainable

In an era marked by growing environmental consciousness, large cardboard tubes shine as eco-friendly alternatives to traditional packaging materials. Made from renewable and biodegradable resources, cardboard is inherently sustainable, with the potential for recycling and repurposing at the end of its lifecycle. By opting for cardboard tubes over non-biodegradable alternatives, businesses can reduce their carbon footprint and contribute to a greener future.

Customization Options

Large cardboard tubes offer ample opportunities for customization to meet specific requirements and preferences. Whether it's adjusting dimensions, adding reinforcements, or incorporating branding elements, manufacturers can tailor these tubes to suit individual needs. This versatility extends to printing capabilities, allowing businesses to showcase logos, artwork, or instructional information directly on the tube surface, enhancing brand visibility and customer engagement.

Easy Handling and Storage

Unlike bulky and unwieldy alternatives, large cardboard tubes are remarkably easy to handle and store. Their lightweight design facilitates effortless maneuverability, whether it's loading onto trucks or positioning within warehouse facilities. Moreover, their cylindrical shape lends itself to efficient stacking and nesting, maximizing storage space and optimizing logistical operations. This streamlined approach to handling and storage translates to tangible cost savings and operational efficiencies for businesses.

Challenges and Limitations

Vulnerability to Moisture and Environmental Factors

While large cardboard tubes offer numerous benefits, they are not without their challenges. One of the primary concerns is their vulnerability to moisture and environmental factors. Excessive exposure to water or humidity can compromise the structural integrity of cardboard, leading to warping, weakening, and mold growth. To mitigate this risk, businesses must implement proper storage and handling practices, such as storing tubes in dry environments and utilizing moisture-resistant coatings when necessary.

Limited Load-Bearing Capacity

Despite their impressive strength-to-weight ratio, large cardboard tubes have a limited load-bearing capacity compared to metal or plastic alternatives. This constraint restricts their suitability for certain applications requiring heavy-duty support or prolonged exposure to weight-bearing stresses. While engineers continuously explore ways to enhance the structural integrity of cardboard tubes through innovative designs and materials, businesses must exercise caution when selecting tubes for high-load scenarios.

Recycling and Disposal Concerns

While cardboard is inherently recyclable, the recycling process for large cardboard tubes presents unique challenges due to their size and composition. Unlike smaller cardboard packaging, which can be easily broken down and processed, large tubes may require specialized equipment and facilities for recycling. Moreover, tubes contaminated with adhesives, coatings, or other materials may pose recycling challenges, leading to increased disposal costs and environmental impact. To address these concerns, businesses should prioritize waste reduction, recycling initiatives, and responsible end-of-life management practices.

Innovations and Future Trends

Development of Reinforced and Specialty Cardboard Tubes

In response to growing demand for high-performance packaging and structural solutions, manufacturers are exploring advanced techniques to enhance the strength and durability of cardboard tubes. This includes the development of reinforced cardboard composites, incorporating materials such as fiberglass, carbon fiber, or biodegradable polymers to augment structural integrity and load-bearing capacity. By leveraging these innovations, businesses can expand the scope of applications for cardboard tubes while maintaining their sustainability credentials.

Integration of Technology for Enhanced Functionality

As the boundaries between physical and digital realms blur, cardboard tubes are poised to embrace technology-driven enhancements that elevate their functionality and user experience. This includes the integration of RFID tags, QR codes, or augmented reality markers directly onto tube surfaces, enabling seamless tracking, authentication, and interactive content delivery. By harnessing the power of connectivity, businesses can unlock new opportunities for supply chain optimization, consumer engagement, and data-driven insights.

Expansion of Sustainable Practices in Production and Use

In an era of heightened environmental awareness and regulatory scrutiny, the demand for sustainable packaging solutions continues to grow. Large cardboard tubes are well-positioned to capitalize on this trend, offering a renewable, biodegradable, and recyclable alternative to conventional packaging materials. Moving forward, we can expect to see increased adoption of sustainable practices throughout the lifecycle of cardboard tubes, from eco-friendly manufacturing processes to circular economy initiatives that promote reuse, recycling, and repurposing.

Case Studies and Examples

Architectural Projects Utilizing Large Cardboard Tubes

In the realm of architecture, large cardboard tubes have emerged as innovative building blocks for temporary structures, pavilions, and experimental installations. One notable example is the Serpentine Pavilion, an annual architectural commission in London's Hyde Park, which has featured designs incorporating cardboard tubes as primary structural elements. These visionary projects showcase the creative potential of cardboard tubes in reimagining traditional construction methods and pushing the boundaries of architectural expression.

Success Stories in Packaging and Shipping

Across the globe, businesses are reaping the benefits of large cardboard tubes in packaging and shipping applications. For instance, online retailers have embraced cylindrical packaging solutions to safeguard fragile items such as posters, blueprints, and artwork during transit. By replacing traditional rectangular boxes with custom-sized cardboard tubes, these companies have reduced packaging waste, minimized shipping costs, and enhanced customer satisfaction through secure and eco-friendly packaging solutions.

Art Installations and Sculptures

Artists and designers continue to push the envelope of creativity with large cardboard tubes, transforming them into awe-inspiring installations and sculptures that captivate audiences worldwide. From immersive environments constructed entirely from cardboard tubes to intricate sculptures showcasing the beauty of recycled materials, these artworks blur the lines between architecture, design, and environmental activism. By harnessing the inherent versatility and sustainability of cardboard tubes, artists spark dialogue, inspire imagination, and challenge perceptions of art and innovation.

Industrial Applications in Various Sectors

In the industrial landscape, large cardboard tubes find applications beyond traditional packaging and shipping. For instance, manufacturers of textiles, films, and paper products rely on cardboard tubes as cores for winding and spooling materials during production. By providing a stable and customizable platform for material handling, these tubes contribute to operational efficiency, product quality, and supply chain optimization across diverse sectors.

Embracing the Future with Large Cardboard Tubes

In conclusion, large cardboard tubes embody the perfect synergy of strength, versatility, and sustainability, making them indispensable assets in modern industry and creative endeavors. From their humble origins as packaging materials to their transformative potential in architecture, art, and beyond, these cylindrical wonders continue to shape the world around us in unexpected ways. As we navigate towards a more sustainable and interconnected future, the humble cardboard tube stands tall as a symbol of innovation, resilience, and endless possibility.