The Ultimate Guide to Round Cardboard Tubes: Uses, Benefits, and Innovations

Aktie

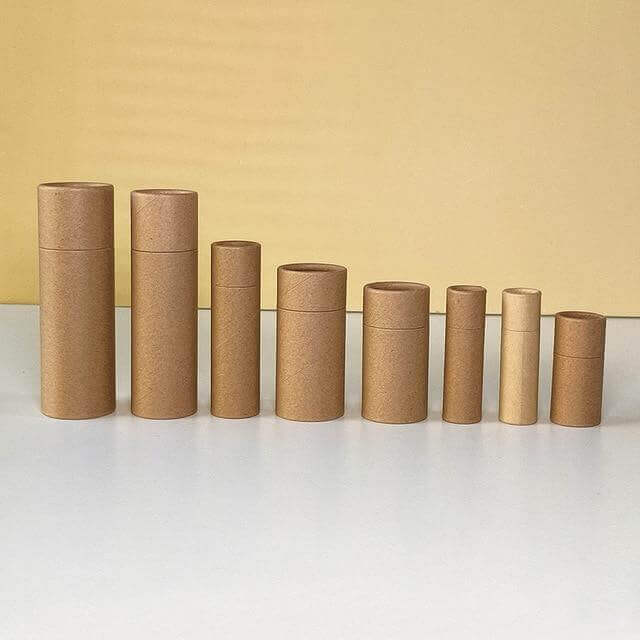

Round cardboard tubes are a staple in many industries, offering both practicality and a spectrum of uses that range from simple packaging solutions to creative crafting bases. Whether encasing beauty products, safeguarding fine writing instruments, or neatly packaging garments, these sturdy cylinders are essential. In this guide, we'll explore the various aspects of round cardboard tubes, including how they are made, where to buy them, how to make them stronger, and the innovative ways they are being used in today's economy.

Section 1: Understanding Round Cardboard Tubes

What are Cardboard Tubes Called?

In the world of packaging and crafts, cardboard round tubes go by many names, indicative of their diverse uses. Often referred to as paper tubes, tube packaging, etc., they are indispensable in shipping, offering protection to posters and documents. In their robust form known as fiber tubes, they cater to industrial needs, encasing materials that require extra strength for transit. As paper tubes, they are the preferred choice for crafts, providing a foundation for creativity.

What is a Round Tube Box?

A Round Tube Box is an evolution of these tubes, tailored for packaging elegance and practicality. It's a cylindrical container crafted from layers of cardboard, which not only ensures structural integrity but also stands out for its aesthetic appeal. It’s often employed to house premium products like artisanal spirits or luxury cosmetics, owing to its unique form that differentiates from standard boxy packaging. The design of a Round Tube Box is not just about looks; it offers excellent protection with its inherent strength, making it a sophisticated and secure choice for transporting delicate items. With customization options, from size to print, it meets a range of specifications, reinforcing brands and delighting recipients with a superior unboxing experience.

Section 2: Where to Buy Cardboard Tubes

When considering where to purchase cardboard tubes, options abound. You may turn to online retailers, which offer the convenience of browsing a broad range of sizes and types from the comfort of your screen. Local paper mills could be a source for more personalized service and possibly better bulk pricing. Specialty craft stores are your go-to for more bespoke or specialized tubes, often catering to specific industries or creative endeavors.

Choosing the right supplier, such as Esytube, which caters to various industries including cosmetics, stationery, and clothing, involves weighing several factors. Quality is paramount; the tubes must be durable enough to protect their contents. Price is always a consideration—finding a balance between cost and quality can affect your bottom line. Finally, customization options can play a crucial role, especially if you need specific sizes or branding for your products. A supplier like Esytube, offering packaging solutions tailored to diverse needs, can provide this versatility, ensuring that your product stands out in today's competitive market.

Section 3: Manufacturing Process

Production Stages of Round Tube Boxes:

- Material Selection: The journey begins with choosing the right materials. High-quality cardboard is pivotal for its strength and durability. The cardboard thickness, density, and even the type of pulp used can impact the final product's sturdiness and appearance.

- Design and Planning: The design phase is crucial. Accurate dimensions are required to ensure the tubes fit their intended use. Customization in terms of diameter, length, and even wall thickness is considered here.

- Printing and Decoration: Before shaping, the cardboard may be printed with desired patterns, logos, or colors. Advanced printing techniques can ensure high-resolution images and vibrant colors that last.

- Die-Cutting and Shaping: With designs in place, the flat cardboard is then cut and rolled into a cylindrical shape. This is typically done with a die-cutting machine that ensures precision.

- Assembly: The round tubes are assembled, and end caps are often added. The joints may be secured with adhesives or other fastening methods to ensure they stay intact during use.

- Finishing Touches: Lamination, varnishing, or embossing can be applied to enhance the visual appeal and tactile experience, as well as to provide additional protection.

Points to Consider in Round Tube Boxes Production:

- Material Quality: A high-grade material is non-negotiable. It's not just about the aesthetics but also about the protective quality and the overall durability of the tube box.

- Design Precision: The precision of design measurements dictates how well the final product functions. The attention to detail here can make or break the usability of the tube.

- Sustainability Practices: As businesses and consumers become more environmentally conscious, using recycled materials or ensuring the cardboard is recyclable can be a significant selling point.

Throughout this process, quality control checks are essential to maintain standards and meet client specifications. Innovations in materials and processes are constantly evolving, allowing manufacturers to create more durable, attractive, and eco-friendly round tube boxes.

Section 4: How to Make Cardboard Tubes Stronger?

Enhancing the strength of cardboard tubes can be achieved through a variety of techniques, each contributing to a more robust and durable end product.

Layering and Material Quality: By adding multiple layers of cardboard, you effectively double or even triple the material’s thickness, increasing its strength and carrying capacity. Using new, unused cardboard is recommended as it is generally stronger than recycled material, and selecting corrugated cardboard with a wavy inner layer can offer additional reinforcement.

Construction and Adhesives: A strong wrap around the exterior can also improve strength. Options for this include watered-down glue, although experimenting with the measurements is essential to find the right balance. A more durable alternative is epoxy resin, which creates a hard shell around the tube, offering extra protection and reinforcement. Internally, adding a layer of fibreglass within the tube can also add significant strength due to its lightweight yet robust properties.

Correct Selection: Beyond reinforcement, ensuring that you select the right type of tube for your needs from the outset can save time and resources. Considering the required size and thickness for the intended purpose is crucial, and opting for industrial-strength cardboard tubes when necessary can preclude the need for additional reinforcement.

Section 5: Practical Applications

What Can You Do with Round Cardboard?

Round cardboard tubes are not only functional but versatile. In the beauty industry, they become elegant containers for cosmetics, offering protection and a canvas for branding. Stationery companies use these tubes for pencils and pens, ensuring safe transport and a striking presentation. In fashion, they offer a unique packaging alternative for items like scarves or t-shirts.

Maximizing Protection and Security with Mailing Tubes

For mailing purposes, their cylindrical shape provides an inherently strong structure that's ideal for sending posters, blueprints, or documents. To maximize their protective qualities, it’s best to use bubble wrap or foam as cushioning inside the tubes. Sealing the ends with secure caps and clear tape ensures the contents stay intact. For delicate items, mark the tubes with "Fragile" or "Handle with Care" to prompt careful handling. These practices ensure that items reach their destination in pristine condition, leveraging the round cardboard tubes' full potential for security and efficiency.

Section 6: Economic and Environmental Impact

Bulk Shipping Tubes for Efficiency

When shipping items in bulk, the use of round cardboard shipping tubes presents numerous economic and environmental benefits. Firstly, these tubes are lightweight yet sturdy, which reduces shipping costs by minimizing the overall weight of packages. Additionally, their cylindrical shape allows for more tubes to fit within a given space, maximizing cargo capacity and reducing the number of trips needed for delivery. This not only cuts down on fuel consumption but also on the emissions associated with transportation.

Embracing Cost-Effectiveness and Efficiency with Mailing Tubes

Mailing tubes offer several cost benefits:

- Lower Material Costs: They require less material than traditional boxes.

- Reduced Shipping Rates: Their shape and light weight can lower shipping costs.

- Less Packing Material: Tubes naturally require less packing material, saving on both costs and environmental resources.

Harnessing the Versatility of Cardboard Tubes

Cardboard tubes stand as a testament to simplicity and ingenuity in packaging, serving a myriad of industries with unparalleled efficiency. They underscore a commitment to sustainability and cost-effectiveness, echoing the demands of contemporary commerce for environmentally friendly practices and economic prudence.

The strength and adaptability of cardboard tubes make them indispensable, ensuring that products arrive safely and stylishly to consumers. As we advance, the versatility of these tubes continues to evolve, promising innovative uses and an enduring presence in our global market. They are not merely packaging; they are a symbol of sustainable progress and the art of practical design.