Digital printing sample VS Machine-printed sample

Aktie

When we are going to customize a paper tube packaging for our products, it is a natural thought to get a sample before the mass-production. But I guess you are not quite sure about the options you have on customizing paper tubes. And that is why I write this blog.

Here are 3 options when customers ask for a sample. The first one is the Machine-printed sample. The next is digital printing sample. And the last one is the structure sample.

The Premium Option: Machine-Printed Samples

Machine-printed sample is the most accurate one among these 3 options. It is totally the same as the final products you received, including the colors, size, pattern, and logo. So, we also call it pre-production sample. If you have a stringent requirement to color the packaging, machine printed sample is absolutely the perfect option for you to check and fix the problem in time. But at the same time, machine-printed sample involves many production processes like plate making, color separation and so on, which brings machine-printed sample higher production costs than other types. And that is to say, this type costs the most money. And trust me, this superb sample will be worth the money.

The Color Difference: Digital Printing Samples Versus Machine-Printed Samples

The Color Difference: Digital Printing Samples Versus Machine-Printed Samples

Digital printing sample is only different from the previous machine-printed sample in its color. It's important to note that these two samples originate from separate printing machines, and this variance between the two machines accounts for the dissimilarity. So, when you receive a digital sample, its color is usually brighter than the final object. If you have designed a bronzing embossed logo on your packaging, you will see it on the digital printing sample. And if you are expected to put a layer of glossy film on the paper tube, the digital printing sample would do that too. I don't want to seem verbose, but allow me to say it again: the one and only variance between digital printing sample and machine-printed sample is the color.

But if you want to make sure that the pattern of the design is in the right place, or whether the effect of bronzing is consistent with the expectation, a digital printing sample is more suitable. Out of these 3 types, it is definitively the most cost-effective choice. Besides that, the process of digital printing is relatively simple. And that means it takes much less time to produce a sample and you can get a sample in a very short time.

Basic Validation: The Purpose of Structure Samples

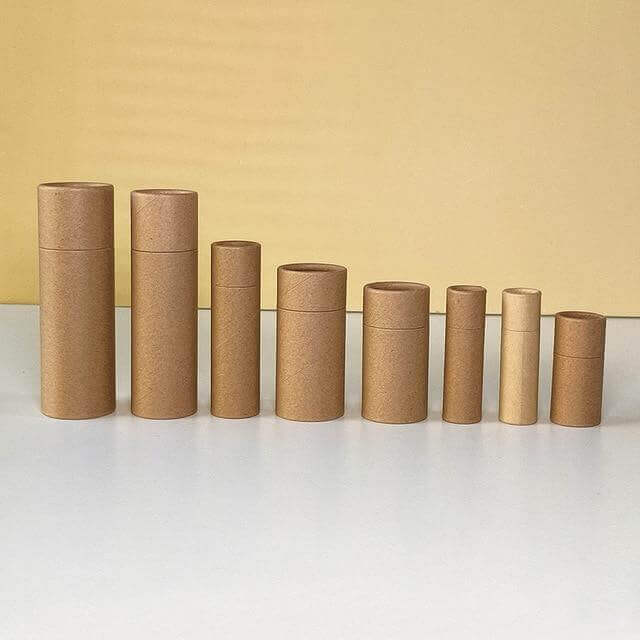

Structure sample is offered for clients who need to check the material of the packaging and the size. There is no printing pattern, logo, bronzing, and lamination on the surface of the paper tube. It is totally a blank paper tube. In the past few years, I have met some clients who what to customize a paper tube for their products with uncomplicated designs. And in this case, I would recommend them the structure sample that is without any design, but enough to check the size and quality. And don’t forget the cost. This kind of sample is the cheapest one. You do not have to spend as much as the previous 2 types to get a sample. Moreover, if we have the size you need in store, you could even get it for free. And all you need to bear is the freight.

Selecting the Right Sample and Expert Assistance Offered by Esytube

Selecting the Right Sample and Expert Assistance Offered by Esytube

And that is all 3 types of samples in Esytube. You can choose different samples according to your needs, but if you are not sure which one is more suitable for you, you can also send an email to our experts to help you. And you know paper tube has a wide application, and it fits well in packaging all kinds of goods. As a manufacturer specializing in custom paper tubes, we have produced paper tubes for lip balm, lipstick, and cosmetic item for our consumers. You can get all kinds of paper tubes from us. What is more, we have many tubes in store, if you are interested in them, you can also click here to know more.