Custom printing packaging: the 7 major types of printing technologies

Compartir

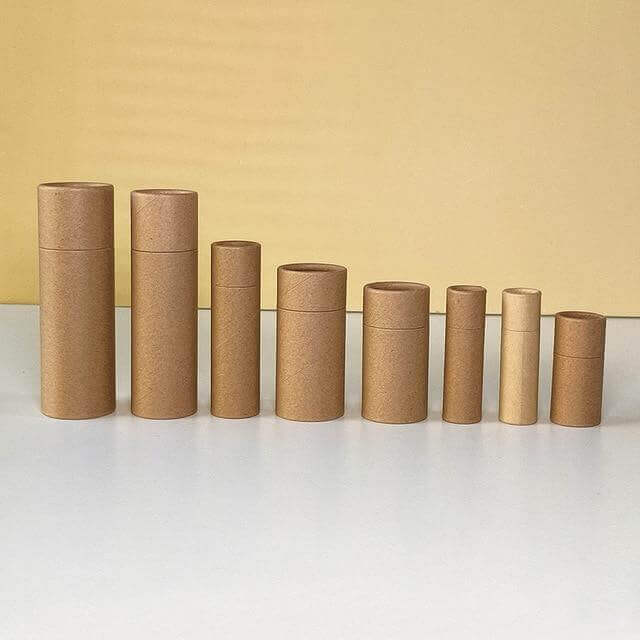

We all know that it is necessary to get a sample before mass production. And the reason for this is to ensure your design is well-presented. There are many factors that affect the performance of the paper tube packaging during its production, such as materials, colors, size, printing method and so on. Only when these influencing factors work together can you receive the perfect paper tube packaging. All of these deserve detailed descriptions. But out of the consideration of the express effect, I will only introduce the printing method at this time.

There are many printing technologies available on Esytube. Spot UV, Silver Stamping, Golden Stamping, Embossing, Debossing, Matt Lamination, Glossy Lamination. You can choose any of them according to your design when you customize a paper tube packaging, 2 or more are also allowed. And in the following content, I’ll introduce them to you one by one.

Spot UV

Spot UV is a kind of printing method with the help of ultraviolet light to cure/dry the UV ink. As its name “spot” implies, this kind of printing technology could be applied to parts of a packaging, like the logo, pattern, or lines. It has a very different tough compare to the parts without Spot UV. You can easily feel it is more textured and smoother.

Golden Stamping

The principle of Golden Stamping is the same as that of Silver stamping. Both of them are all using a metal plate (stamping die) to contact the foil. And then heated the plate to press down onto the foil and the cardboard, and transfer the thin layer of the foil film into the surface of the cardboard.

This printing method is popular in the luxury packaging industry because of its eye-catching effect and outstanding applicability. It works well on almost all kinds of products.

Silver stamping

This is one of the printing technologies to result in a highly reflective effect and will add the packaging some dynamic element when you move/shake it. And this kind of printing method is commonly applied in high-end brands to enhance brand value and promote sales. It is a printing method to add the packaging to a metallic silver sheen, which can perfectly fit any brand.

Embossing

Embossing is a printing method to make a three-dimensional effect. It always works with other printing technology like the above hot foil stamping. Embossing requires a custom template with your desired design and the material to be embossed (cardboard). Then use the template to press the material with the help of a machine. You can feel it protruding when you touch it, which is much more pronounced than the effects of the printing technologies mentioned before.

Debossing

Debossing works the same way like embossing. But embossing is to protrude the pattern, logo, and words from the surface while the debossing is to dent the elements. And as I said before, this kind of printing method has a unique performance of the final effect of the packaging, plus the hot foil stamping printing technology. I believe no one can refuse the vivid artwork. It makes sense why luxury packaging likes to use this kind of printing method.

Matt Lamination

When it comes to matt lamination, people always regard it a coating technique rather than a printing technology. That is because matte lamination is to heat and pressure a thin, matte plastic film onto the surface of the printed cardboard. And packaging after this process would add an aesthetic appeal, which is what people usually call understated luxury.

Glossy Lamination

Compare to matt lamination, glossy lamination is absolutely more color vibrancy. Same as the process of matt lamination, it is to apply the glossy plastic film to the printed cardboard to add a touch of sophistication and refinement to the paper tube packaging. Also, it provides a protective layer to the packaging against possible damage like scratches.

Custom paper tubes here

All these mentioned printing technologies are accessible for you to choose. And if you want to apply multiple technologies to your desired packaging, but not sure what combination can achieve the best effect, don’t hesitate to connect us. Esytube has many experienced experts in the packaging industry. You could send an email at sales@esytube.com. Also, we provide customized services for paper tubes. If you want to get the fitted packaging for your products, you can also send us an email including the following information.

- Colors: How many colors are there on the inside and outside of the paper tube?

- Size: Diameter × Length

- Logo: Printing method, colors

- Quantity Desired