How to Make Paper Tube Packaging: A Guide for Businesses

Share

Paper tube packaging is growing in popularity because it is eco-friendly, recyclable, and biodegradable. Many brands now choose paper tubes over plastic to reduce waste and improve their brand image. As a professional factory, Esytube has seen how custom paper tubes help businesses achieve both sustainability and value. This guide explains how to make paper tube packaging step by step.

1. What Is Paper Tube Packaging?

Paper tube packaging is a cylindrical container made by winding multiple layers of paperboard into a rigid tube. Its basic structure includes an inner core, outer wrap, wall thickness, and surface finish. Known for being durable, recyclable, and customizable, paper tube packaging is widely used as a sustainable alternative to plastic containers.

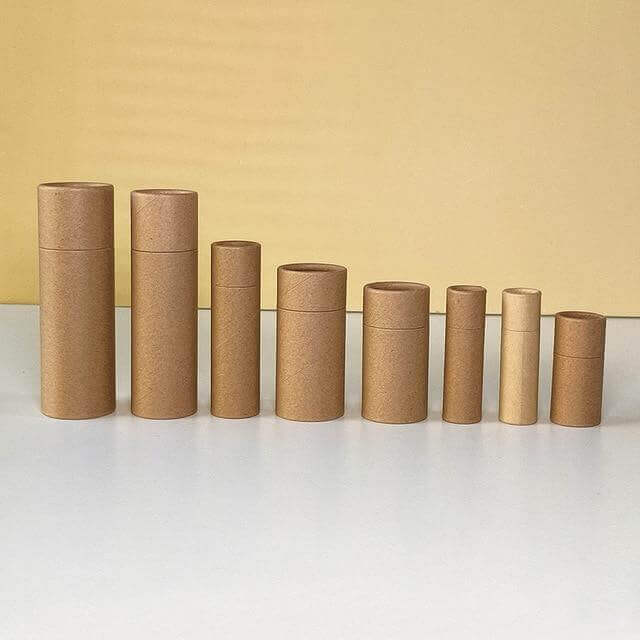

2. Types and Styles of Paper Tube Packaging

By Industry

• Mailing Tubes – For safe shipping of documents, blueprints, and posters.

• Food Packaging Tubes – Designed for tea, coffee, snacks, and other dry foods.

• Cosmetic Tubes – Popular for lip balms, essential oils, and skincare products.

• Gift Tubes – Used for candles, gift sets, and creative retail packaging.

• Industrial Tubes – Heavy-duty cores for textiles, tapes, and films.

By Style (Popular Designs)

• Push-Up Tubes – Bottom-push design, eco-friendly and widely used for lip balms, solid perfumes, and deodorants.

• Twist-Up Tubes – Base-twist mechanism for controlled dispensing, popular for lip care and cosmetic sticks.

• Shaker Tubes – Perforated cap for even powder release, ideal for spices, baby powder, and cosmetic dusting.

• Paper Jars – Wide-mouth style for easy access, often used in food, supplements, and skincare products.

3. Materials Used in Paper Tube Packaging

Paper Materials

• Kraft Paper – Strong, natural-looking, and widely used for eco-friendly packaging.

• White Cardboard – Clean and smooth surface, ideal for colorful printing.

• Recycled Paperboard – A sustainable choice made from post-consumer materials.

Surface Finishes

• Printing (custom logos and designs)

• Lamination (matte or glossy protection)

• Hot Foil Stamping (premium metallic effects)

• Embossing / Debossing (tactile textures for branding)

Eco-Friendly Properties

• All paper tube materials are recyclable and biodegradable, making them a sustainable alternative to plastic packaging.

4. How to Make Paper Tube Packaging (Step by Step)

Step 1: Select Paper and Layers

Choose the right base material depending on your product — kraft paper for a natural look, white cardboard for high-quality printing, or recycled paperboard for sustainability. Decide how many layers are needed, as thicker walls provide more strength for heavy or fragile items.

Step 2: Tube Winding

Roll and bond the paper layers into a cylindrical shape using either spiral winding (paper wound at an angle, ideal for continuous production) or convolute winding (paper wrapped around in layers, providing extra strength).

Step 3: Precision Cutting

Once the tube is formed, it is cut into the desired length using specialized cutting machines. This ensures consistency so that each tube fits the intended product perfectly.

Step 4: Add Inner Liner or Coating

For special applications, an inner liner or coating is applied. For example, food-grade liners for tea and coffee, oil-resistant coatings for cosmetics, or moisture barriers for powders.

Step 5: Printing & Surface Finishing

The outer layer is customized with branding. Options include offset printing, lamination (matte or glossy), foil stamping for a luxury look, or embossing to add texture. At the factory, advanced winding and printing machines guarantee precise dimensions and smooth finishes.

Step 6: Assembly and Closure

Finally, the tube is completed by attaching components such as paperboard lids, metal ends, or custom inserts. This step ensures the paper tube packaging is ready to store, protect, and showcase the product.

5. Benefits of Custom Paper Tube Packaging

1. Eco-Friendliness

Custom paper tubes are made from renewable materials such as kraft paper and recycled paperboard. They are 100% recyclable and biodegradable, making them a sustainable alternative to plastic. With natural resistance to moisture and oil, they also ensure safer storage and transportation.

2. Brand Value

Paper tube packaging delivers a premium unboxing experience. Its smooth surface and cylindrical shape allow for high-quality printing, foil stamping, and embossing. This not only enhances product presentation but also strengthens brand identity and positions products as more sophisticated in the eyes of consumers.

3.Product Protection

The cylindrical structure resists compression and can include inner coatings for moisture or oil resistance.

3. Low MOQ Flexibility

Unlike many traditional packaging suppliers, paper tubes can be produced in low minimum order quantities (MOQ). This flexibility makes them ideal for startups, small businesses, or seasonal product lines, allowing brands to access eco-friendly, customized packaging without high upfront costs.

6. Applications of Paper Tubes in Various Industries

• Retail & E-commerce – Protects products during shipping and enhances the unboxing experience, making online orders more appealing to customers.

• Food & Beverage – Keeps products fresh with food-grade liners and moisture resistance, ideal for tea, coffee, snacks, and spices.

• Cosmetics & Personal Care – Replaces plastic packaging in lip balms, deodorants, and skincare items, meeting consumer demand for eco-friendly beauty solutions.

• Gifts & Premium Products – Adds luxury appeal with options like foil stamping, embossing, or custom printing, perfect for candles and gift sets.

• Industrial Applications – Provides strength and durability for cores, tapes, and construction materials, supporting heavy-duty performance.

Let’s Create Your Paper Tube Solution

Learning how to make paper tube packaging highlights why it’s the right choice for modern businesses — sustainable, durable, and customizable. From food and cosmetics to gifts and industrial use, paper tubes are shaping the future of packaging.

Ready to switch to sustainable packaging? With 15+ years of experience, Esytube specializes in eco-friendly custom paper tubes and cardboard tubes wholesale. Contact us today to explore low MOQ, premium-quality solutions tailored to your brand.